Development of Coconut Husk Based Drilling Fluid

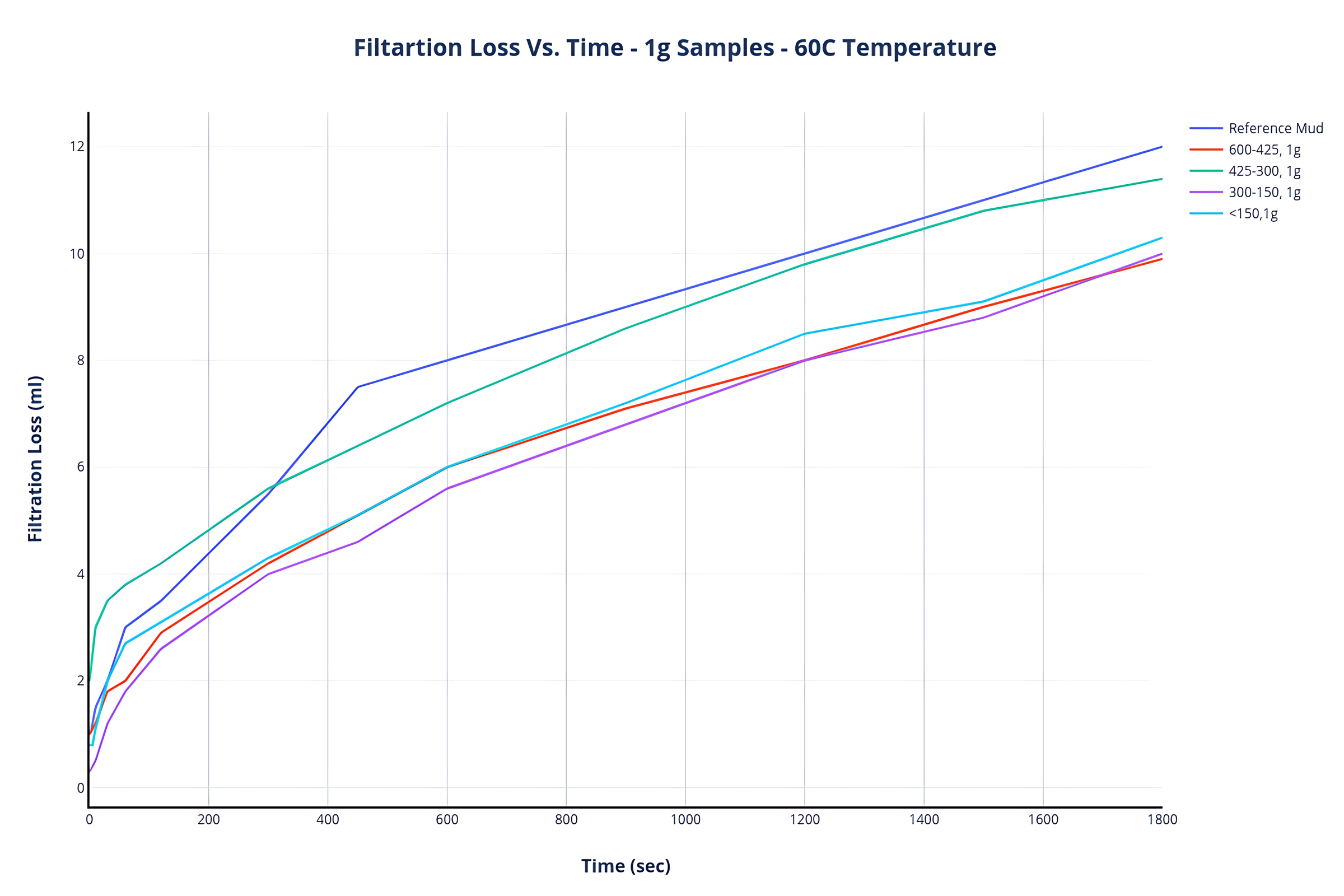

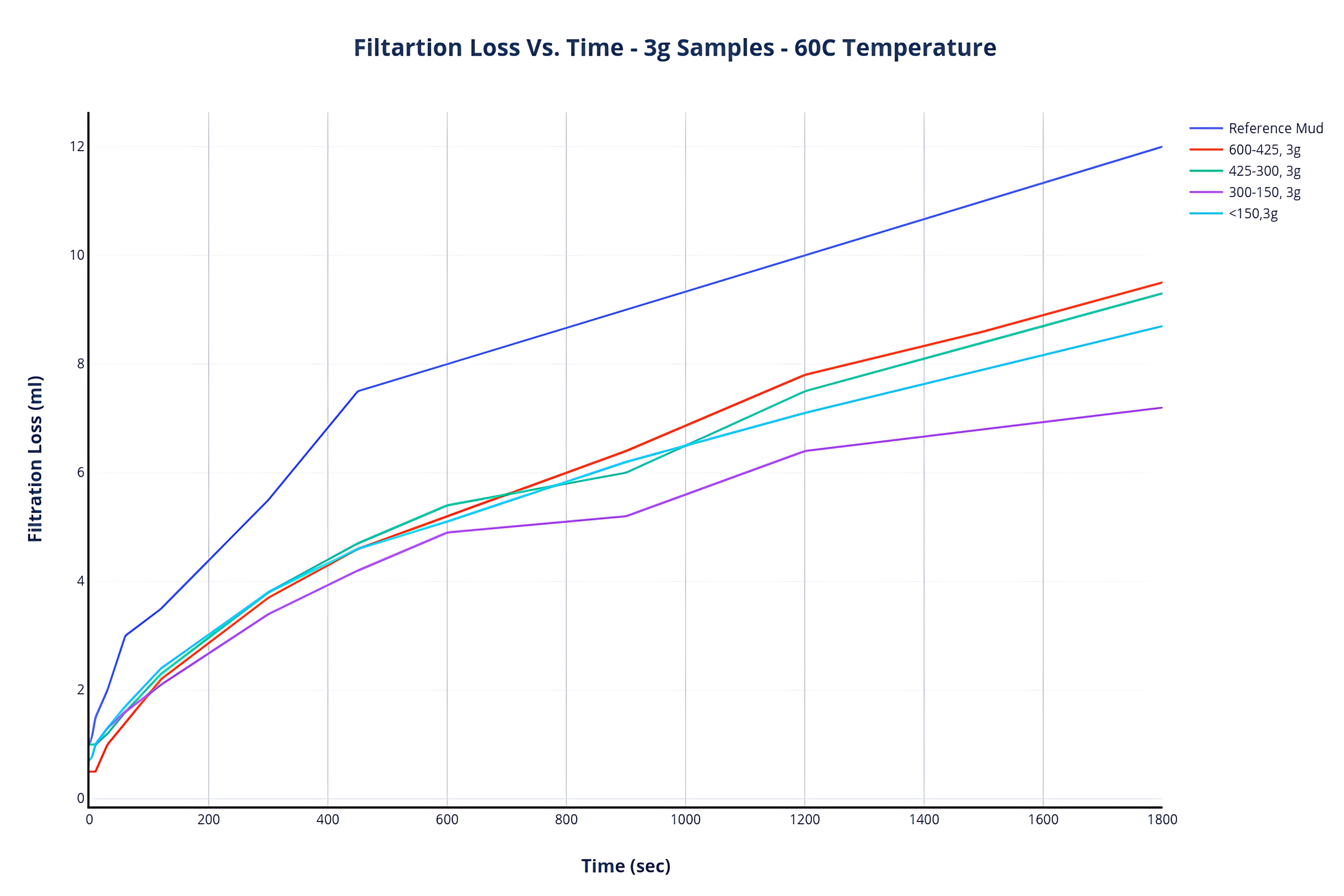

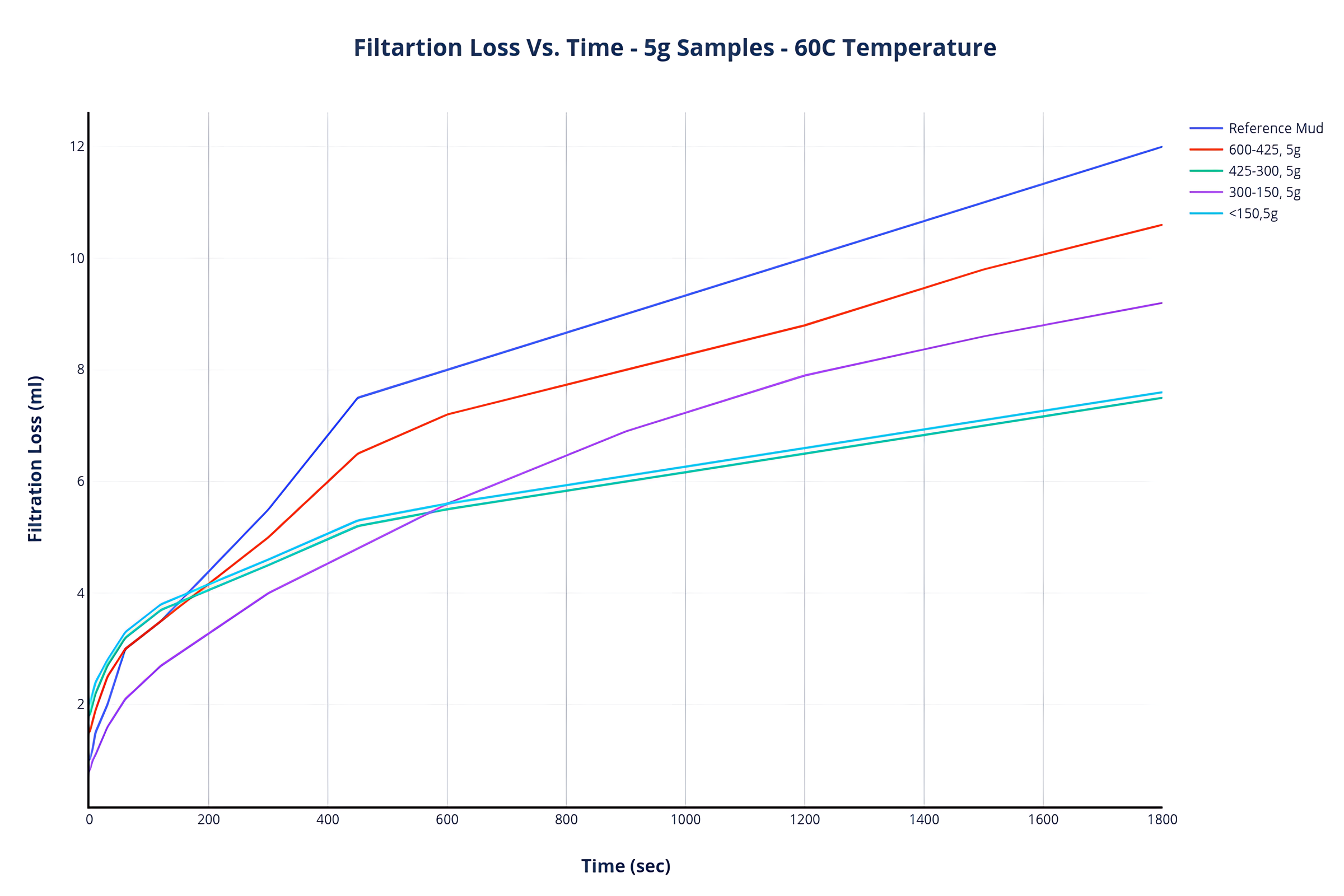

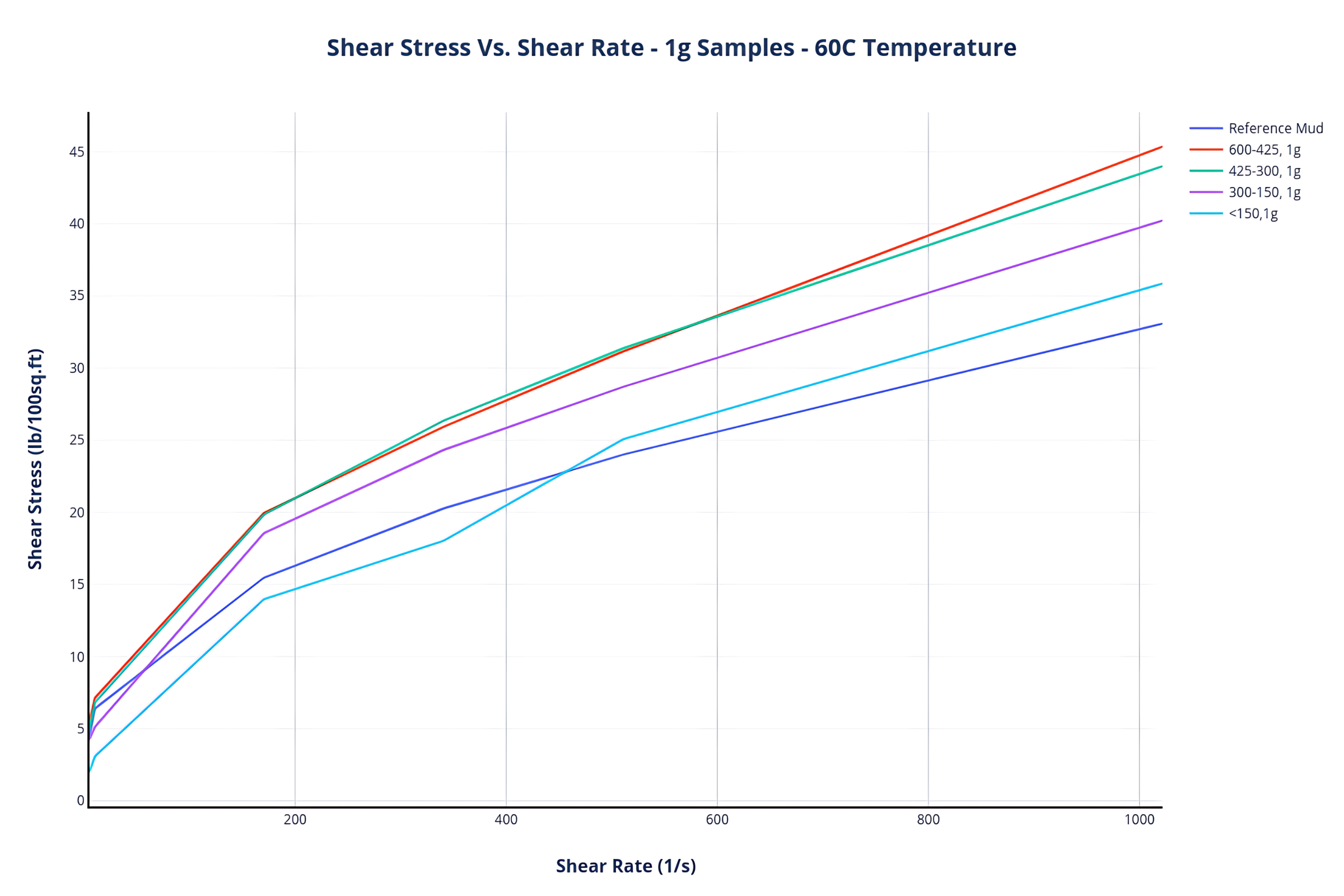

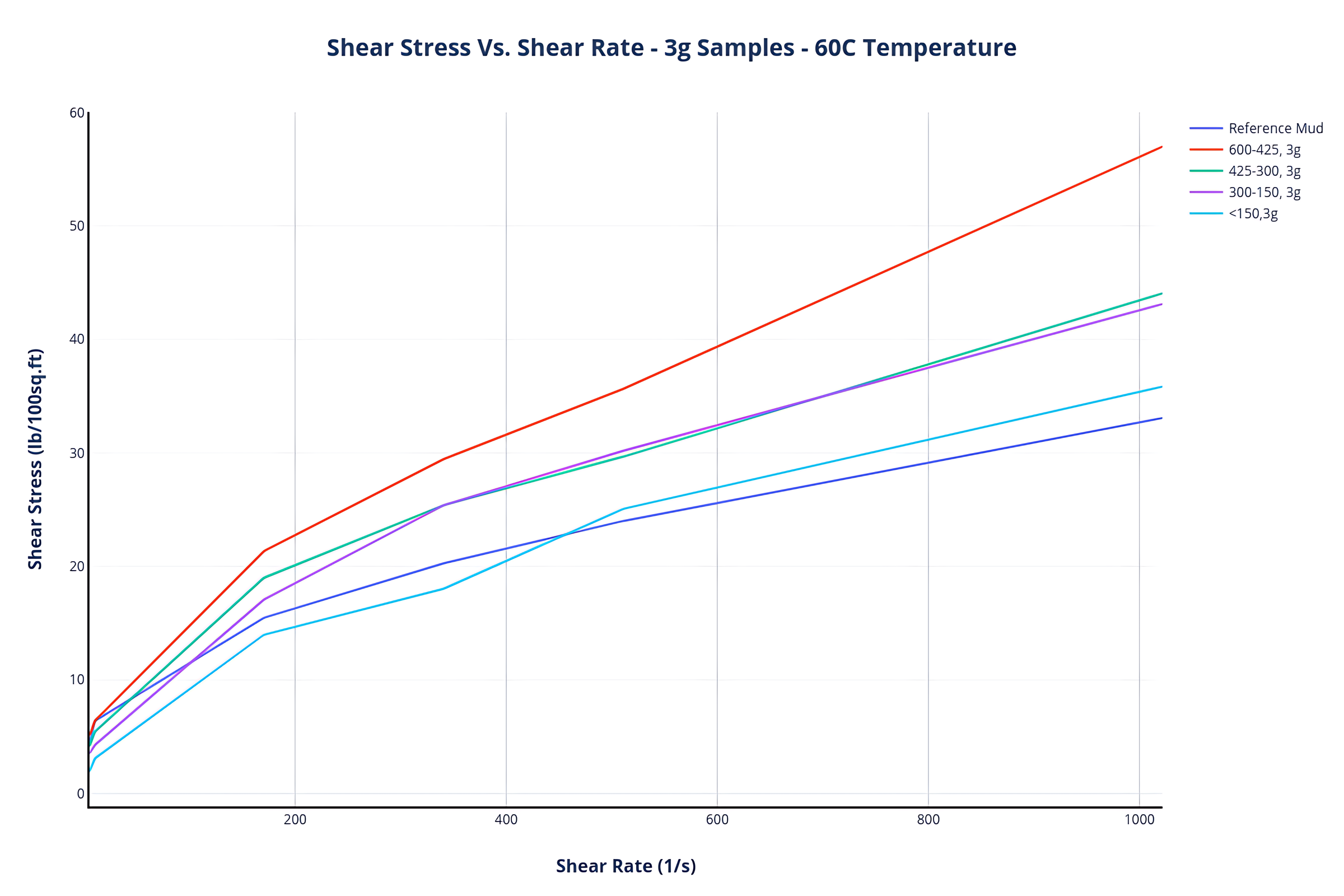

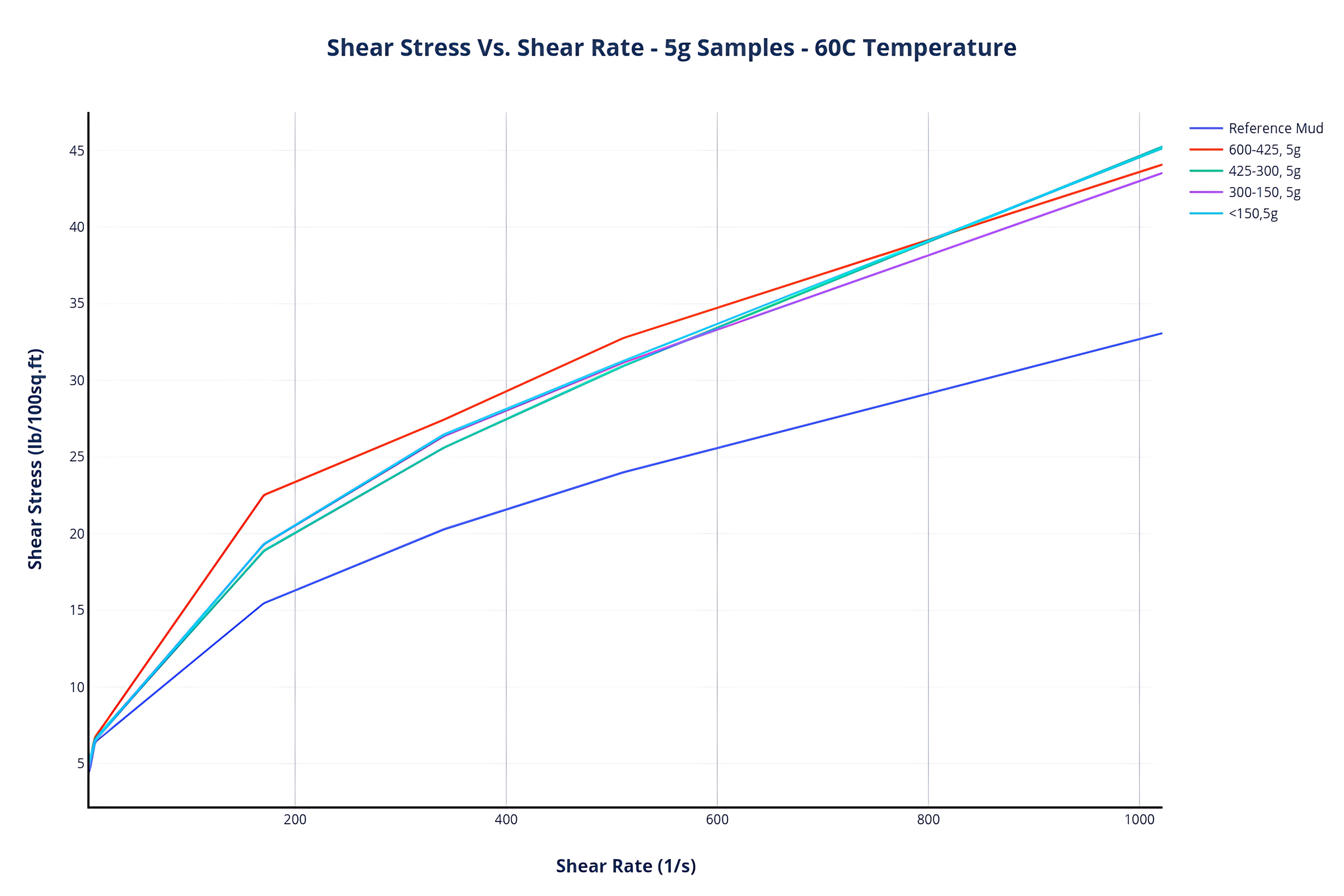

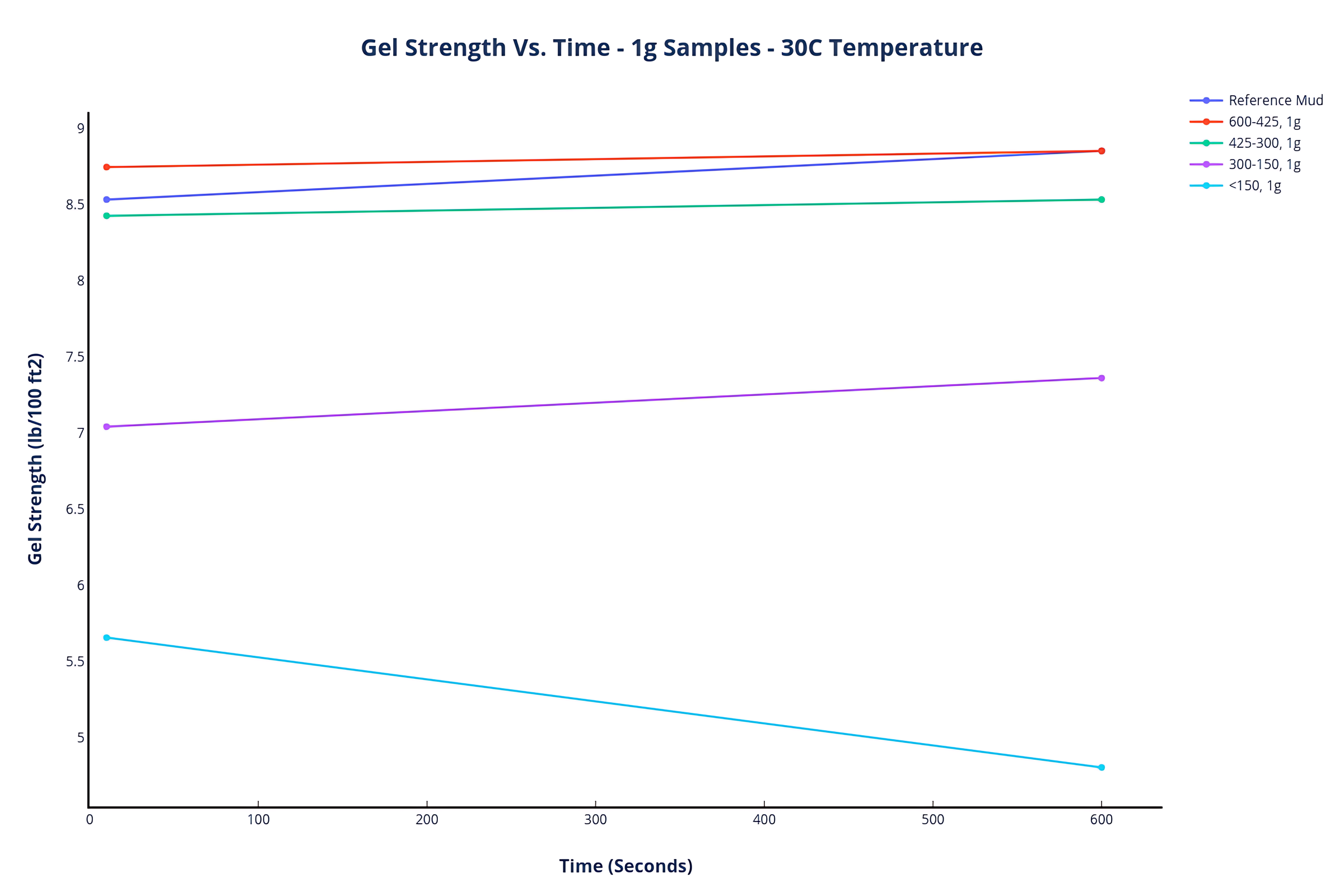

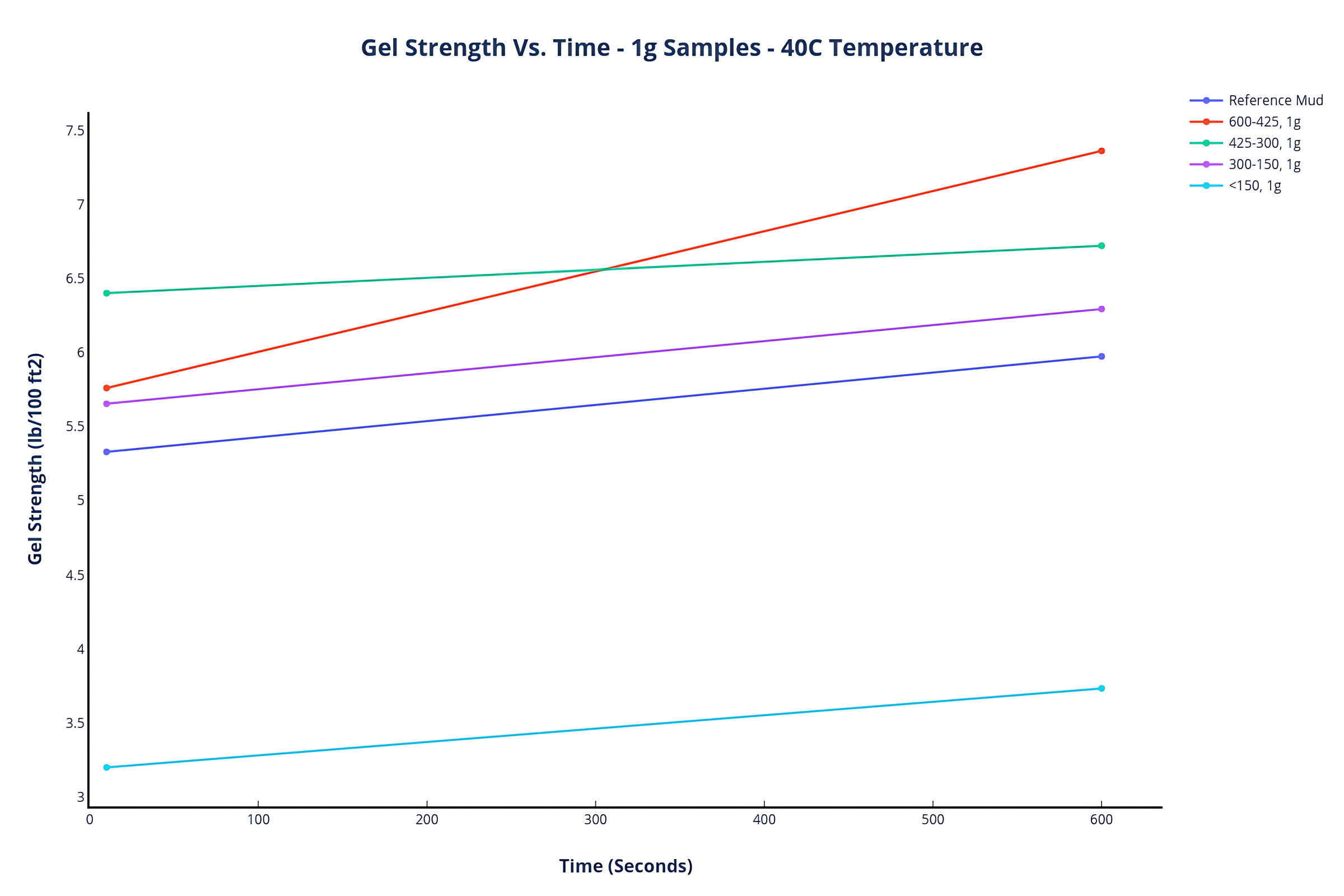

The significance of using coconut husk in drilling fluid lies in its ability to provide an effective, sustainable, and cost-efficient solution for lost circulation and related challenges. The project purely focused on the development of different variants of coconut husk-based drilling fluid (based on the concentration and sizes of the husk) and a comparative study of the same to use them as a Loss Circulation Material (LCM) in drilling operations. Different lab experiments were conducted on the prepared mud samples and the comparative study was performed by analyzing different properties such as Fluid Loss, Shear Stress vs. Shear Rate, Gel strength, Viscosity, etc.